1. Product Overview:

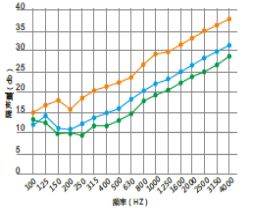

Vinyl sound barrier material contains natural minerals and does not contain lead,unrefined aromatic oil, or asphalt. lt has a significant effect on reducing the penetration of airborne noise and can significantly improve the insertion loss(sound insulation) from pipeline insulation systems against pipeline noise. Compared with similar products, it has a better noise reduction effect especially in low and intermediate frequencies.

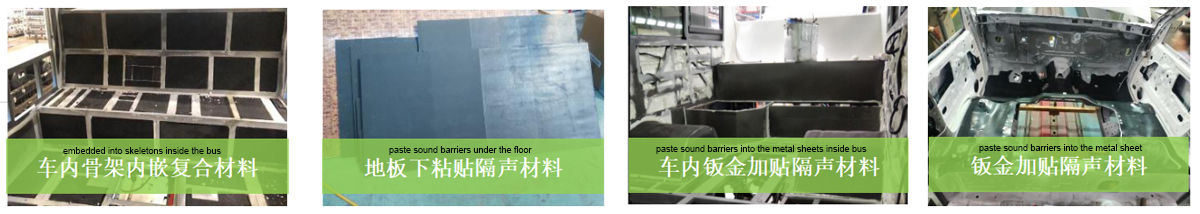

Application: Underfloor shock absorption/Underfloor sound insulation/Wheel housing sound insulation/Body stamping parts sound insulation/Shock absorber pad/Rear and side cabin door composite material/Engine compartment composite material.

2. Parameters

|

Technical specs |

|

| Flame retardant properties |

▶ GB 38262-2019 ▶ JT/T 1095-2016 ▶ European Bus ECE R-118 |

| Stable performance temperature | -40℃——+150℃ |

|

High density |

≥2500kg/m3 |

| Tensile strength |

≥2.6Mpa(2mm)

|

| Dimension | ||

| Product | Size/thickness(mm) | Package |

| ICET ® vinyl sound barrier | 1220 * 2440 * 1.2 | sheet |

|

ICET ® vinyl sound barrier |

1220 * 2440 * 2.0 |

sheet |

|

ICET ® vinyl sound barrier |

1220 * 2440 * 3.0 |

sheet |

3. Product Description

| Advantages |

• It can significantly reduce the penetration of airborne sound propagation noise and has good airborne sound insulation performance • The material is non-metallic, resistant to corrosion, rust and aging, resistant to decomposition, and has excellent UV and ozone resistance • Compared with metal soundproof materials, the material can prevent rust and oxidation on the surface without spraying, improve weather resistance, and reduce surface treatment costs • Tensile strength: ≥ 2.6Mpa (2mm); • Fracture elongation rate: ≥ 100% (2mm); • Fire resistance: Oxygen index>32%, self extinguishing • Weighted sound reduction index 2.0mm: Rw ≥ 29dB; • Weighted sound reduction index 1.2mm: Rw ≥ 21dB; |

|||