Products

Products

Location:Home > Products > ICET® Composite Products

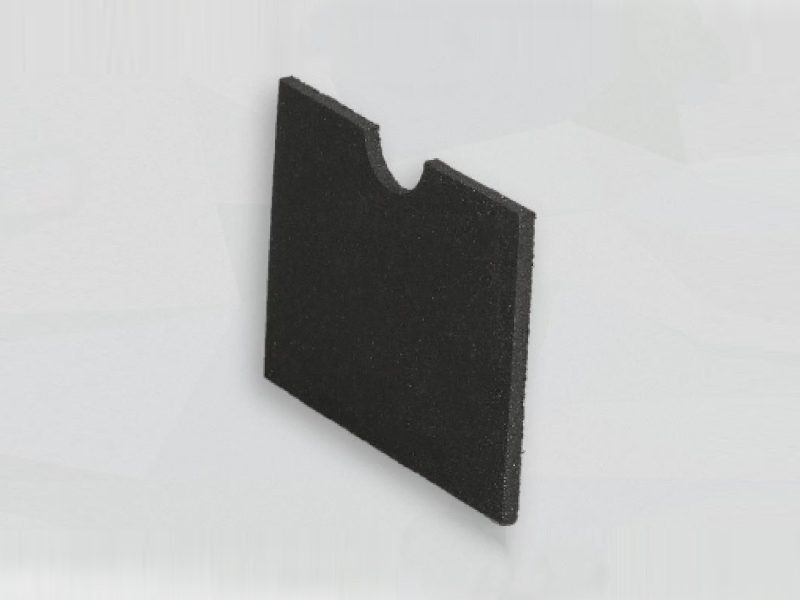

ICET ® V200 Damping Plate / Magnetic V200 Damping Plate

1. Product Overview:

The V200 environmentally friendly damping plate is made by mixing synthetic rubber and resin, with high damping, low density, low VOC, low odor, high adhesion performance and other characteristics, meeting the requirements of GB/T 27630. It is particularly suitable for replacing asphalt damping plates and conforms to the trend of environmental weight reduction.

Application: Used for shock absorption and noise reduction of various transportation vehicles and other mechanical vibrating bodies.

2. Parameters

| Technical Parameter | |||

|

Testing items |

V200 damping plate |

Magnetic V200 damping plate |

Detection |

|

Appearance |

Dark gray solid sheet No pits or wrinkles on the surface |

Dark gray solid sheet No pits or wrinkles on the surface |

visualization |

|

Density(g/cm³) |

1.4 ±0.1 |

2.0 ±0.1 |

SMTC 9 544 001 |

|

Damping loss factor,0-40ºC |

Thick 2mm,≥0.15 |

Thick 2mm,≥0.25 |

GB/T 18258-2000 |

|

Solid content,% |

≥99.5 |

SMTC 5 400 196 |

|

|

Flexibility |

Bending 180 ° without cracking,deformation,or fracture |

SMTC 3 544 001 |

|

| Caking |

No adhesion |

SMTC 5 400 097 |

|

|

Hot melt performance |

160℃*30mins No poor adhesion |

SMTC 5 400 167 |

|

|

24H moisture resistance |

The damping pad is undamaged and has not deteriorated |

SMTC 6 330 003 |

|

|

Low temperature impact |

No breakage or detachment |

SMTC 5 400 167 |

|

|

Thermal stability |

The damping pad is undamaged and has not deteriorated |

SMTC 3 451 003 |

|

|

Anti overheating 120min,200℃ |

The damping pad is undamaged and has not deteriorated |

SMTC 3 451 003 |

|

|

Odor testing |

Normal condition ≤ Level 3, dry condition ≤ Level 3.5 |

SMTC 5 400 012 |

|

|

Salt spray test |

No damage or deterioration |

Neutral salt spray, 720 hours |

|

|

Melting temperature,℃ |

130-140℃,20-30min |

/ |

|

|

Flame retardancy |

meet with GB8410, GB38262 |

GB8410-2006 |

|

|

High and low temperatures alternating |

No harmful damage |

SMTC 5 400 005A 30 cycles |

|

|

Polycyclic hydrocarbons |

pass through |

ZEK-01.4-08 |

|

|

ELV |

pass through |

SMTC 5 500 001 |

|

|

Construction temperature |

130-140℃,20-30min |

/ |

|

|

Storage temperature |

-5-40℃ |

/ |

|

|

Storage period |

12 months from the date of manufacture |

warranty |

|

|

Product characteristics |

||

| characteristic | V200 damping plate | Magnetic V200 damping plate |

| Use position | Vehicle floor area | Areas such as the side panels and headlinner of the vehicle that require magnetic attachment |

|

Function characteristics |

Shock absorption, isolation, buffering, noise reduction, sound insulation |

|

| Core advantages |

Environmentally friendly, low VOC, flame retardant and other properties are better than the requirements of bus manufacturers, and have strong stability without decomposition when heated; High damping, low density, with reinforcement effect, significantly improves the overall NVH performance of the vehicle; Fully meet the requirements of hot melt deformation adhesion and followability, identical to the current hot melt asphalt damping plate laying process, without additional cost. |

|

RecommendMore