Material characteristics

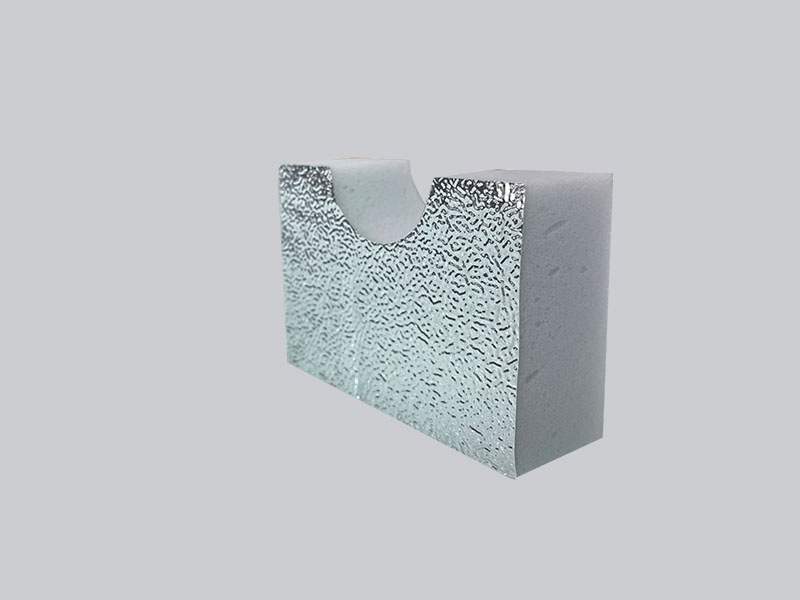

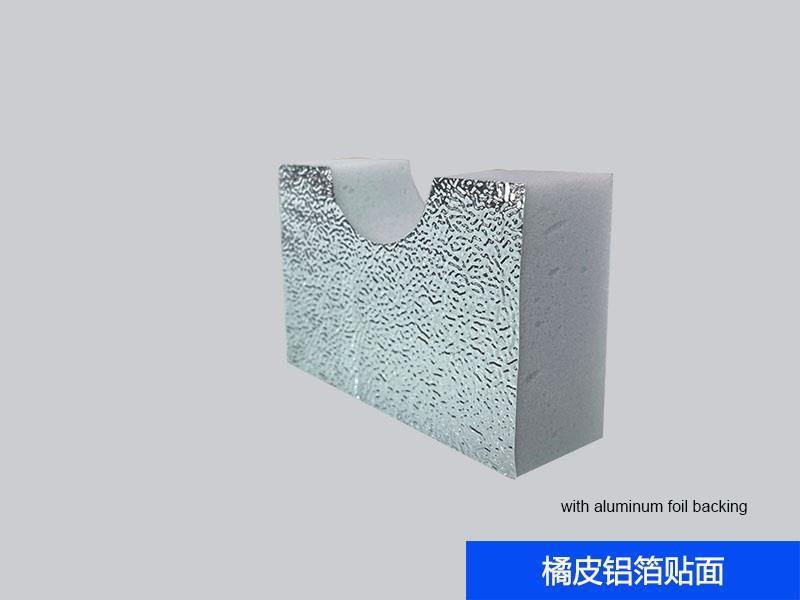

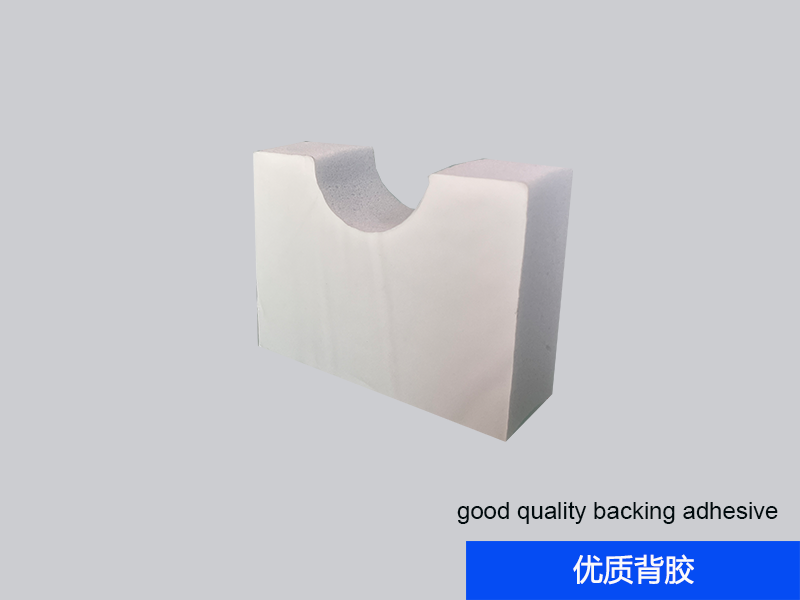

The oil and water repellent process makes the material permanently non-absorbent of water and oil. It can also be coated with anti-corrosion acoustic aluminum foil veneer, and the back can be coated with high viscosity water-based environmentally friendly adhesive. It is mainly used for sound absorption and thermal insulation, and the material meets the latest GB 38262-2019 testing standards for bus.

Advantages Compared with Polyurethane Foam Materials

Item point

Melamine noise reducing material

Foamed polyurethane material

Fire performance

Complies with GB38262-2019 standard and meets rail way standards

EN45545 R1 HL3 Bus Full Life Cycle Flame Retardant Performance Warranty

Poor fire resistance performance after long-term use

Temperature resistance

-50~+150℃

ordinary

Thermal insulation performance

Thermal conductivity 0.031 isolated thermal radiation

Uneven thickness affects insulation and cannot isolate thermal radiation

Sound absorption coefficient

Open-cell structure, excellent noise reduction level

NRC=0.85(50mm)

NRC=0.75(30mm)

Closed cell structure, mainly used for insulation

Hydrophobic

Hydrophobic rate 99.95%, not absorbing moisture or oil stains

Poor aging resistance, prone to spoilage in humid conditions

Environmental performance

Physical process, environmentally friendly, non moldy, odorless

Chemical process, more complex

Construction

Convenient construction and time-saving, available for direct installation and usage.

On-the-spot foaming is affected by temperature, making it difficult to achieve regularly foaming and resulting in low efficiency.

Typical application of materials

Use materials of different thicknesses according to the depth of the body side panels and headliner frame; To meet the construction requirements, materials are usually backed with adhesive and different embossed aluminum foil /fiberglass material for thermal insulation and sound insulation