According to the previous experience in noise controls:

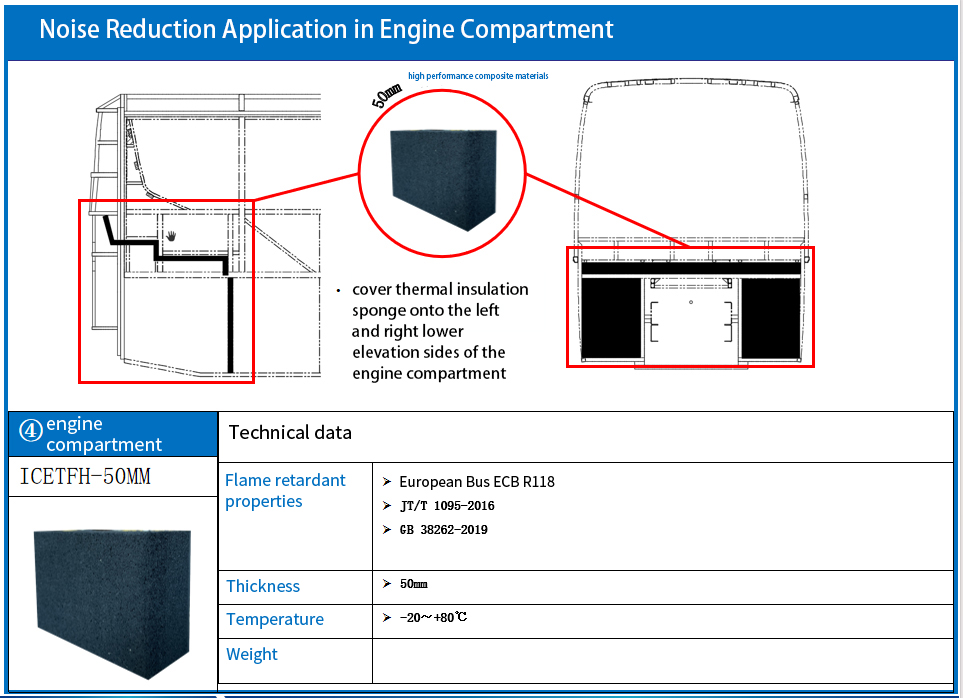

The engine noise of CNG vehicles has a greater impact than the ordinary fuel vehicles. As the vehicle speed increases, the engine influence on the noise inside the bus becomes stronger. So the first step in noise control is to reduce the impact of engine noise inside the bus.

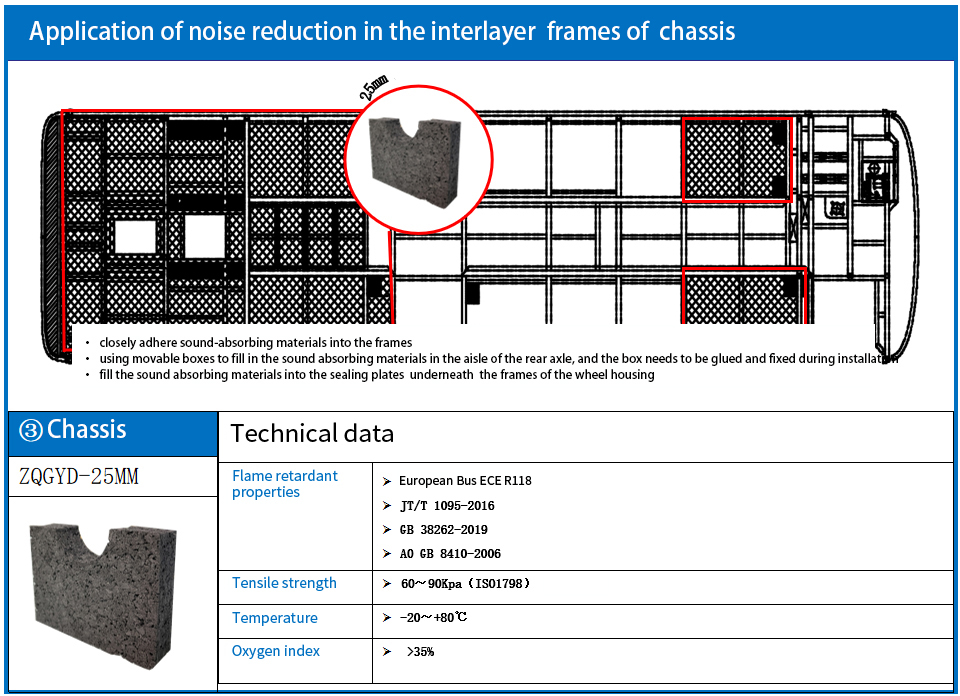

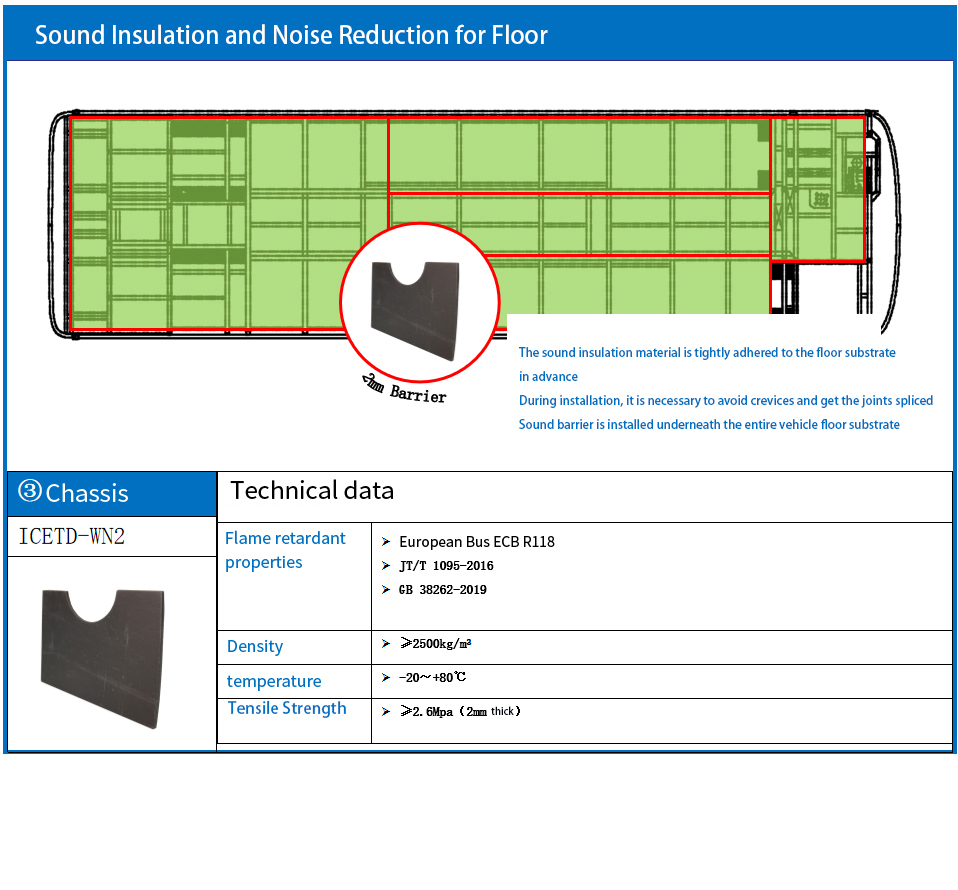

Secondly, the noise generated by tire friction on the ground during vehicle operation (tire noise) also has a significant impact on passengers inside the vehicle. These noises, along with other noises outside the vehicle, are transmitted through the chassis of the vehicle to the interior of the cabin. Therefore, the vehicle chassis noise reduction is also a key link.

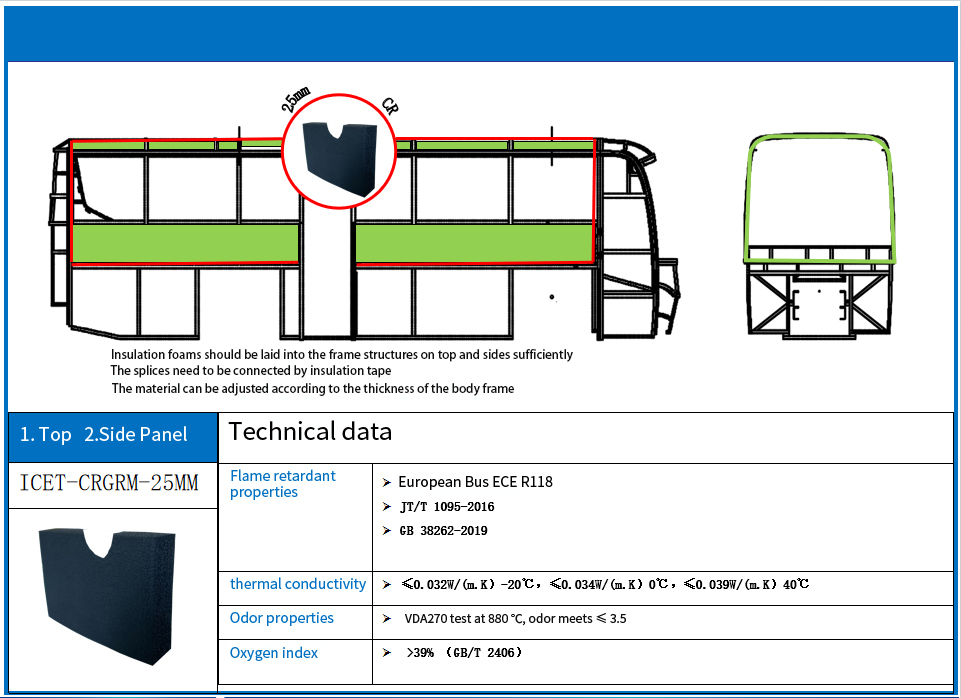

Through experiments and observation of actual vehicles, it was found that polyurethane foam materials undergo aging within 1.5 to 2 years on average ; after aging, polyurethane materials are prone to water vapor and internal brittleness, and are greatly affected by environmental factors. When the internal structure is “invaded” by water vapor, the insulation effect is greatly reduced, and even the heat transfer can be accelerated; in order to deal with this issue, ICET-CRGRM insulation sponge NBR synthetic rubber closed cell foam elastomer insulation material, provides a dual guarantee of comfort and energy saving for passenger buses with its stable and reliable insulation performance.

Noise reduction scheme and effect prediction:

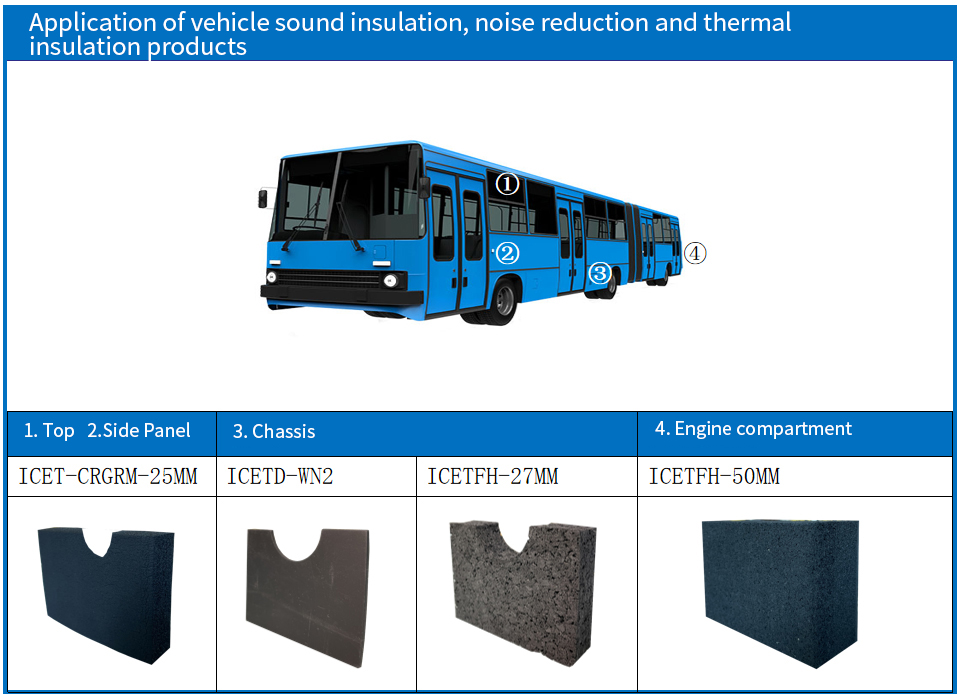

The preliminary design plan is to carry out comprehensive sound absorption and insulation treatment around the engine compartment and under the vehicle floor. 2mm sound barrier material will be laid under the floor, 50mm composite sound absorption and insulation material will be filled in the engine compartment, 27mm composite sound absorption and insulation material will be filled in the engine compartment side door and rear compartment door, and 25mm sound absorption material will be filled under the rear floor (inside the interlayer of frames) from the middle door.

After using this scheme, the average noise in the corresponding area of the bus can be reduced by 4-7 dB under the same working conditions, which means that the sound energy transmitted into the bus compartment is reduced by 40% to 70% compared to the situations without using this proposal.

After replacing the polyurethane foam with ICET-CRGRM thermal insulation sponges, the service life of the material (10-15 years) can be increased (without changing the structural properties of the material), effectively ensuring the comfort for passengers in the vehicle when driving in alternating environments and saving energy consumption; the materials meet high environmental and flame retardant standards both domestically and internationally, effectively ensuring the safety.

| Module | Project | No. | Application area | Materials |

|

A |

Engine compartment noise reduction |

1 | Inside the engine compartment |

ICETFH-50MM |

| 2 | Side and rear cabin doors |

ICETFH-27MM |

||

|

B |

Chassis noise reduction |

1 | Underneath the vehicle floor |

ICETD-WN2 |

| 2 | Inside the frame interlayer of the vehicle body |

ZQGYD-25MM |

||

|

C |

Body insulation |

1 | Top of the bus body |

ICET-CRGRM-25MM |

| 2 | Body side panels |

ICET-CRGRM-25MM |

Precautions for Material Installation

• The sound-absorbing material has a certain degree of elasticity, and the size can be cut with a tolerance of about+5mm, which can better seal the boundary after release.

• All welding edges between the material laying surface, skeleton frames and metal sheets, especially those with leaks, must be sealed with sealant first.

• In the areas closest to the sound source, when installing sound insulation materials, they must be continuous. If they need to be disconnected due to the process, sealant should be used to seal the disconnected seam with the structure.

• The backing paper of the material needs to be torn off to ensure that the backing adhesive is tightly and effectively adhered to the bonding surface, avoiding the formation of cavities.

• The sound insulation material under the bamboo reinforcement board of the vehicle body needs to be fully laid. First, it should be installed as a whole with the bamboo reinforcement board. Then, sufficient sealant should be applied to the skeleton frames at all junctions, and then the floor should be installed onto the floor skeleton.

• Although the material comes with adhesive backing, it is still recommended to spray resin glue on the adhesive surface for a more reliable effect, especially for the construction on the engine compartment top.